Below are the rare earth element companies in the U.S.A. including their key mining or processing facilities.

| Company |

Stock Symbol |

Top Mine/Facility |

Location |

| MP Materials |

MP |

Mountain Pass Mine – The only active rare earth mine in the U.S., producing neodymium-praseodymium (NdPr) for high-performance magnets. |

California |

| Ucore Rare Metals |

UURAF |

Alaska Strategic Metals Complex – A planned rare earth processing facility using proprietary RapidSX™ separation technology. |

Alaska |

| Rare Element Resources |

REEMF |

Bear Lodge Project – An advanced-stage rare earth development site with high-strength permanent magnet elements. |

Wyoming |

| American Rare Earths |

ARRNF |

Halleck Creek Project – One of the largest rare earth deposits in the U.S., with strong economic potential for NdPr oxide production. |

Wyoming |

| Texas Mineral Resources |

TMRC |

Round Top Deposit – A rare earth and critical mineral extraction site with high concentrations of heavy rare earth elements. |

Texas |

Rare earth elements—they’re everywhere! From your smartphone to wind turbines, these mighty metals power modern technology and drive innovation. But here’s the kicker: despite their name, they’re not all that rare! The real challenge? Mining and refining them efficiently, especially within the United States.

In this guide, we’ll dig into the rare earth industry, uncover its role in national security, and spotlight the key U.S. companies making waves in this critical field. So, buckle up—because the science behind rare earths is about to get electrifying!

Understanding the U.S. Rare Earth Industry

Rare earth elements—despite their name—aren’t all that rare! These 17 metallic elements, including neodymium, dysprosium, and yttrium, are the backbone of modern technology. They’re in your smartphone, electric vehicles, wind turbines, and even military defense systems. Their unique magnetic, optical, and conductive properties make them indispensable for high-tech applications, from lasers to satellites.

Now, here’s the challenge: the U.S. relies heavily on imports for rare earths, with China controlling the vast majority of global production and refining. That’s a problem for national security and technological independence. To fix this, the U.S. is ramping up domestic mining and processing efforts, with companies like MP Materials leading the charge. But refining rare earths is tricky—it requires specialized facilities and a whole lot of chemistry.

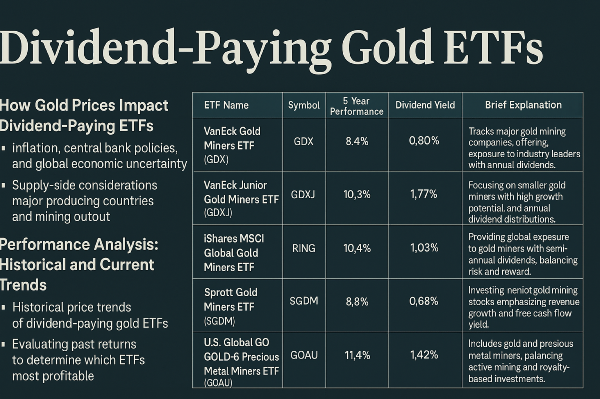

Investors looking to cash in on rare earths have a few options. Rare earth stocks are shares in individual companies that mine, refine, or manufacture rare earth-based products. These can be volatile, depending on global supply chains and geopolitical tensions. ETFs (Exchange-Traded Funds), on the other hand, bundle multiple rare earth-related stocks into one investment, offering diversification. Commodity investments, like futures contracts, focus on the raw materials themselves, rather than the companies that produce them.

Sources:

Major U.S. Rare Earth Companies

The U.S. rare earth industry is rapidly expanding as companies work to secure domestic supplies of these critical elements. From mining and refining to advanced separation technologies, these firms are driving innovation and reducing reliance on foreign sources. Below are some of the leading U.S. rare earth companies making waves in this essential sector.

MP Materials is the largest rare earth producer in North America, operating the Mountain Pass mine in California. The company specializes in extracting and refining neodymium-praseodymium (NdPr), a critical component in high-performance magnets used in electric vehicles, wind turbines, and defense applications. In 2024, MP Materials achieved record-breaking production, delivering over 45,000 metric tons of rare earth oxides (REO) contained in concentrate. The company has also expanded into magnet production, with its Texas facility set to become the first fully integrated rare earth magnet production site in the U.S..

MP Materials is actively working to reduce reliance on Chinese processing by developing domestic refining capabilities. The company has invested nearly $1 billion to establish a complete supply chain from mine to magnet, ensuring a stable and secure rare earth supply for U.S. industries. Despite facing short-term financial challenges due to the cessation of rare earth concentrate exports to China, MP Materials remains committed to reshoring rare earth production and strengthening national security.

Sources:

Ucore Rare Metals is focused on developing rare earth separation technologies within the U.S., particularly through its proprietary RapidSX™ technology. The company has secured $18.4 million in funding from the U.S. Department of Defense to scale up its Louisiana Strategic Metals Complex (SMC), which aims to process both light and heavy rare earth elements. This facility is expected to play a crucial role in reducing U.S. dependence on Chinese rare earth refining.

Ucore’s long-term strategy includes expanding its refining capabilities beyond Louisiana, with plans for additional Strategic Metals Complexes in Alaska and Canada. The company is positioning itself as a key player in the North American rare earth supply chain, leveraging government support and partnerships to accelerate commercialization. With its advanced separation technology, Ucore aims to provide a reliable domestic source of rare earth elements for defense, clean energy, and high-tech industries.

Sources:

Rare Element Resources is advancing the Bear Lodge Rare Earth Element Project in Wyoming, aiming to establish a secure domestic supply chain for critical rare earths. The company has constructed a rare earth processing and separation demonstration plant in Upton, Wyoming, designed to validate its proprietary extraction technology. This facility is expected to produce up to 10 tons of separated Nd/Pr oxide, supporting ongoing discussions with strategic partners and potential customers.

Despite facing delays in plant operations due to necessary design modifications, Rare Element Resources remains committed to refining its technology for commercial-scale production. The company has secured funding from the Wyoming Energy Authority and is collaborating with General Atomics to enhance its processing capabilities. If successful, the Bear Lodge project could become a significant domestic source of rare earth elements, reducing reliance on foreign suppliers.

Sources:

American Rare Earths is developing rare earth projects in Arizona and Wyoming, with its flagship Halleck Creek project positioned as one of the largest rare earth deposits in the U.S. The company’s updated scoping study highlights strong economic potential, estimating an NPV of $558 million for its 3 Mtpa base case and $1.17 billion for its 6 Mtpa expansion. Halleck Creek is expected to produce thousands of metric tons of total rare earth oxides annually, including NdPr oxide.

Unlike many rare earth projects that face permitting challenges on federal land, Halleck Creek benefits from state land tenure, allowing for accelerated development. American Rare Earths is positioning itself as a first-mover in the U.S. rare earth industry, aiming to establish a fully integrated domestic supply chain independent of foreign processing. With growing demand for rare earths in clean energy and defense applications, the company’s strategic location and scalable production potential make it a promising player in the sector.

Sources:

Texas Mineral Resources is focused on developing rare earth elements and other strategic minerals at its Round Top deposit in Texas. The company’s joint venture partner, USA Rare Earth, has announced plans to become a publicly traded company, further solidifying its role in domestic rare earth production. Round Top is unique in its high concentration of heavy rare earth elements, which are critical for defense and high-tech applications.

Texas Mineral Resources is actively working to re-establish the U.S. as a leader in rare earth production and refining. The company’s mission is to provide a secure domestic supply of heavy rare earths, reducing reliance on foreign sources. With ongoing exploration and development efforts, Texas Mineral Resources is positioning itself as a key player in the strategic minerals sector.

Sources:

U.S. Rare Earth Mining and Processing Facilities

The United States is ramping up efforts to mine and process rare earth elements domestically, reducing reliance on foreign suppliers. These facilities play a critical role in extracting, refining, and separating rare earths essential for technology, clean energy, and national security. Below are some of the key sites shaping the future of U.S. rare earth production.

Mountain Pass Mine is the only active rare earth mining operation in the U.S., located in California’s Mojave Desert. MP Materials extracts rare earth ore from one of the richest deposits globally, focusing on neodymium-praseodymium (NdPr), which is essential for high-performance magnets used in electric vehicles, wind turbines, and defense applications. The mine produces more than 10% of the world’s rare earth supply and operates as a zero-net-discharge facility, minimizing environmental impact while ensuring a stable domestic supply of critical materials.

MP Materials has re-established processing capabilities at Mountain Pass, integrating mining, milling, flotation, separation, and refining into a single location. The company is working to reduce reliance on Chinese refining by expanding domestic processing infrastructure, including a magnet production facility in Texas. With continued investment and government support, Mountain Pass is positioned to strengthen the U.S. rare earth supply chain.

Sources:

Bear Lodge Project, located in Wyoming, is an advanced-stage rare earth development site owned by Rare Element Resources. The deposit is rich in high-strength permanent magnet rare earths, including neodymium, praseodymium, samarium, and terbium. The company has identified a near-surface, high-grade zone that could accelerate early cash flows once mining operations commence. Wyoming’s pro-business environment and existing infrastructure make Bear Lodge a promising domestic rare earth source.

Rare Element Resources is developing a rare earth processing and separation demonstration plant in Upton, Wyoming, designed to validate its proprietary extraction technology. The facility aims to produce up to 10 tons of separated Nd/Pr oxide, supporting strategic partnerships and potential commercial production. With funding from the Wyoming Energy Authority and collaboration with General Atomics, Bear Lodge is positioned to contribute to U.S. rare earth independence.

Sources:

Round Top Deposit, located in Texas, is one of the largest rare earth and critical mineral extraction sites in the U.S. Texas Mineral Resources, in partnership with USA Rare Earth, is developing this open-pit mine to produce heavy rare earth elements, lithium, uranium, and other strategic minerals. The deposit is estimated to contain over 1.1 million metric tons of rare earth oxides, making it a significant domestic resource.

The Round Top project benefits from its location on state-owned land, allowing for streamlined permitting and development. Texas Mineral Resources is working to establish a fully integrated rare earth supply chain, including refining and magnet production. With strong economic potential and government backing, Round Top is expected to play a crucial role in securing U.S. rare earth independence.

Sources:

Ucore Rare Metals is developing the Alaska Strategic Metals Complex (SMC), a planned rare earth processing facility near Ketchikan, Alaska. The facility will focus on refining heavy and light rare earth elements using Ucore’s proprietary RapidSX™ separation technology. The company has secured funding from the U.S. Department of Defense to advance its processing capabilities, aiming to establish a domestic rare earth supply chain independent of China.

Ucore’s long-term strategy includes expanding its refining operations beyond Alaska, with additional Strategic Metals Complexes planned in Louisiana and Canada. The company is positioning itself as a key player in North American rare earth processing, leveraging government support and partnerships to accelerate commercialization. With its advanced separation technology, Ucore aims to provide a reliable domestic source of rare earth elements for defense, clean energy, and high-tech industries.

Sources:

The Role of Government Policies in U.S. Rare Earth Development

Rare earth elements—despite their name—are everywhere! They power electric vehicles, wind turbines, and even military defense systems. But here’s the kicker: the U.S. imports most of its rare earths, with China controlling the lion’s share of global production and refining. To fix this, the U.S. is ramping up domestic mining and processing efforts, with federal incentives and funding aimed at reshoring rare earth supply chains. The Department of Energy has allocated millions to support rare earth refining projects, while defense initiatives seek to secure critical materials for national security.

Geopolitical tensions have only heightened the urgency. Trade disputes and export restrictions have disrupted rare earth supply chains, forcing the U.S. to accelerate partnerships with allied nations like Australia and Canada. The goal? Build a resilient, independent rare earth industry that can withstand global market fluctuations. But it’s a race against time—China’s dominance in refining and magnet production remains a formidable challenge.

Sources:

Market Trends and Outlook for U.S. Rare Earth Companies

The rare earth industry is booming! Forecasts show domestic production could grow at a compound annual rate of 9.2% through 2030, driven by surging demand for electric vehicles, defense applications, and consumer electronics. Neodymium and dysprosium—key components in high-performance magnets—are in particularly high demand as automakers shift toward EVs.

To meet this demand, U.S. companies are forming strategic partnerships with allied nations to secure rare earth supplies. Australia, Canada, and Japan are stepping up collaboration efforts, ensuring a diversified supply chain that reduces reliance on Chinese exports. As rare earths become even more critical to global industries, expect continued investment and innovation in domestic production.

Sources:

ESG and Sustainability Considerations

Rare earth mining isn’t exactly eco-friendly. Traditional extraction methods generate toxic waste, contaminate water sources, and disrupt ecosystems. But U.S. companies are working to change that! New sustainability initiatives focus on reducing environmental impact through cleaner refining technologies and responsible mining practices.

The future of rare earth extraction is looking greener, with bioinspired separation techniques and advanced recycling methods gaining traction. Researchers are developing eco-friendly processes that minimize waste and energy consumption, ensuring rare earth production aligns with global sustainability goals.

Sources:

Risks Facing U.S. Rare Earth Companies

China’s rare earth dominance is a major hurdle for U.S. companies. With control over more than 60% of global production and 85% of refining capacity, China sets the pace for pricing and supply. Competing with this monopoly requires massive investment in domestic refining and processing infrastructure.

Supply chain challenges also pose risks. Rare earth mining and refining require specialized facilities, and disruptions—whether from trade restrictions or logistical bottlenecks—can impact production. Market volatility adds another layer of uncertainty, with rare earth prices fluctuating based on geopolitical events and demand shifts.

Sources:

Investment Opportunities in U.S. Rare Earth Stocks

Investors looking to capitalize on rare earths have several options. Rare earth stocks offer direct exposure to mining and refining companies, while ETFs provide diversified portfolios that mitigate risk. Commodity futures allow investors to trade rare earth materials themselves, though they come with higher volatility.

The best strategy? A balanced approach. Investing in domestic rare earth companies with strong growth potential—like MP Materials and Ucore Rare Metals—while diversifying with ETFs can provide stability. As demand for rare earths continues to rise, these investments could offer long-term gains.

Sources:

Conclusion

Rare earth elements are the unsung heroes of modern technology—they’re in everything from your phone to fighter jets! The U.S. is ramping up efforts to mine and process them domestically, but there’s still a long way to go in competing with China’s refining dominance. With sustainable mining practices, advanced separation technologies, and strategic partnerships, the future of rare earths in America is looking bright. Science rules, and rare earths do too—so stay curious and keep exploring how these mighty metals shape the world!

🔥 Hot Topics in Material Stocks – Explore More! 🚀

Looking to level up your investment game? Dive into the hottest material stocks and rare earth sectors with these must-read articles! ⤵️

🏗️ Material Stocks & Sectors

🔥 High-Value Metal Stocks

🎯 Rare Earth & Advanced Materials

🚀 Keep exploring, keep investing! 💡 Let’s unlock the world of materials together!

Rare earth elements—they’re everywhere! From your smartphone to wind turbines, these mighty metals power modern technology and drive innovation. But here’s the kicker: despite their name, they’re not all that rare! The real challenge? Mining and refining them efficiently, especially within the United States.

In this guide, we’ll dig into the rare earth industry, uncover its role in national security, and spotlight the key U.S. companies making waves in this critical field. So, buckle up—because the science behind rare earths is about to get electrifying!

Understanding the U.S. Rare Earth Industry

Rare earth elements—despite their name—aren’t all that rare! These 17 metallic elements, including neodymium, dysprosium, and yttrium, are the backbone of modern technology. They’re in your smartphone, electric vehicles, wind turbines, and even military defense systems. Their unique magnetic, optical, and conductive properties make them indispensable for high-tech applications, from lasers to satellites.

Now, here’s the challenge: the U.S. relies heavily on imports for rare earths, with China controlling the vast majority of global production and refining. That’s a problem for national security and technological independence. To fix this, the U.S. is ramping up domestic mining and processing efforts, with companies like MP Materials leading the charge. But refining rare earths is tricky—it requires specialized facilities and a whole lot of chemistry.

Investors looking to cash in on rare earths have a few options. Rare earth stocks are shares in individual companies that mine, refine, or manufacture rare earth-based products. These can be volatile, depending on global supply chains and geopolitical tensions. ETFs (Exchange-Traded Funds), on the other hand, bundle multiple rare earth-related stocks into one investment, offering diversification. Commodity investments, like futures contracts, focus on the raw materials themselves, rather than the companies that produce them.

Sources:

Major U.S. Rare Earth Companies

The U.S. rare earth industry is rapidly expanding as companies work to secure domestic supplies of these critical elements. From mining and refining to advanced separation technologies, these firms are driving innovation and reducing reliance on foreign sources. Below are some of the leading U.S. rare earth companies making waves in this essential sector.

MP Materials Corp (NYSE: MP)

MP Materials is the largest rare earth producer in North America, operating the Mountain Pass mine in California. The company specializes in extracting and refining neodymium-praseodymium (NdPr), a critical component in high-performance magnets used in electric vehicles, wind turbines, and defense applications. In 2024, MP Materials achieved record-breaking production, delivering over 45,000 metric tons of rare earth oxides (REO) contained in concentrate. The company has also expanded into magnet production, with its Texas facility set to become the first fully integrated rare earth magnet production site in the U.S..

MP Materials is actively working to reduce reliance on Chinese processing by developing domestic refining capabilities. The company has invested nearly $1 billion to establish a complete supply chain from mine to magnet, ensuring a stable and secure rare earth supply for U.S. industries. Despite facing short-term financial challenges due to the cessation of rare earth concentrate exports to China, MP Materials remains committed to reshoring rare earth production and strengthening national security.

Sources:

Ucore Rare Metals Inc (OTC: UURAF)

Ucore Rare Metals is focused on developing rare earth separation technologies within the U.S., particularly through its proprietary RapidSX™ technology. The company has secured $18.4 million in funding from the U.S. Department of Defense to scale up its Louisiana Strategic Metals Complex (SMC), which aims to process both light and heavy rare earth elements. This facility is expected to play a crucial role in reducing U.S. dependence on Chinese rare earth refining.

Ucore’s long-term strategy includes expanding its refining capabilities beyond Louisiana, with plans for additional Strategic Metals Complexes in Alaska and Canada. The company is positioning itself as a key player in the North American rare earth supply chain, leveraging government support and partnerships to accelerate commercialization. With its advanced separation technology, Ucore aims to provide a reliable domestic source of rare earth elements for defense, clean energy, and high-tech industries.

Sources:

Rare Element Resources Ltd (OTC: REEMF)

Rare Element Resources is advancing the Bear Lodge Rare Earth Element Project in Wyoming, aiming to establish a secure domestic supply chain for critical rare earths. The company has constructed a rare earth processing and separation demonstration plant in Upton, Wyoming, designed to validate its proprietary extraction technology. This facility is expected to produce up to 10 tons of separated Nd/Pr oxide, supporting ongoing discussions with strategic partners and potential customers.

Despite facing delays in plant operations due to necessary design modifications, Rare Element Resources remains committed to refining its technology for commercial-scale production. The company has secured funding from the Wyoming Energy Authority and is collaborating with General Atomics to enhance its processing capabilities. If successful, the Bear Lodge project could become a significant domestic source of rare earth elements, reducing reliance on foreign suppliers.

Sources:

American Rare Earths Limited (OTC: ARRNF)

American Rare Earths is developing rare earth projects in Arizona and Wyoming, with its flagship Halleck Creek project positioned as one of the largest rare earth deposits in the U.S. The company’s updated scoping study highlights strong economic potential, estimating an NPV of $558 million for its 3 Mtpa base case and $1.17 billion for its 6 Mtpa expansion. Halleck Creek is expected to produce thousands of metric tons of total rare earth oxides annually, including NdPr oxide.

Unlike many rare earth projects that face permitting challenges on federal land, Halleck Creek benefits from state land tenure, allowing for accelerated development. American Rare Earths is positioning itself as a first-mover in the U.S. rare earth industry, aiming to establish a fully integrated domestic supply chain independent of foreign processing. With growing demand for rare earths in clean energy and defense applications, the company’s strategic location and scalable production potential make it a promising player in the sector.

Sources:

Texas Mineral Resources Corp (OTC: TMRC)

Texas Mineral Resources is focused on developing rare earth elements and other strategic minerals at its Round Top deposit in Texas. The company’s joint venture partner, USA Rare Earth, has announced plans to become a publicly traded company, further solidifying its role in domestic rare earth production. Round Top is unique in its high concentration of heavy rare earth elements, which are critical for defense and high-tech applications.

Texas Mineral Resources is actively working to re-establish the U.S. as a leader in rare earth production and refining. The company’s mission is to provide a secure domestic supply of heavy rare earths, reducing reliance on foreign sources. With ongoing exploration and development efforts, Texas Mineral Resources is positioning itself as a key player in the strategic minerals sector.

Sources:

U.S. Rare Earth Mining and Processing Facilities

The United States is ramping up efforts to mine and process rare earth elements domestically, reducing reliance on foreign suppliers. These facilities play a critical role in extracting, refining, and separating rare earths essential for technology, clean energy, and national security. Below are some of the key sites shaping the future of U.S. rare earth production.

Mountain Pass Mine (MP Materials, NYSE: MP)

Mountain Pass Mine is the only active rare earth mining operation in the U.S., located in California’s Mojave Desert. MP Materials extracts rare earth ore from one of the richest deposits globally, focusing on neodymium-praseodymium (NdPr), which is essential for high-performance magnets used in electric vehicles, wind turbines, and defense applications. The mine produces more than 10% of the world’s rare earth supply and operates as a zero-net-discharge facility, minimizing environmental impact while ensuring a stable domestic supply of critical materials.

MP Materials has re-established processing capabilities at Mountain Pass, integrating mining, milling, flotation, separation, and refining into a single location. The company is working to reduce reliance on Chinese refining by expanding domestic processing infrastructure, including a magnet production facility in Texas. With continued investment and government support, Mountain Pass is positioned to strengthen the U.S. rare earth supply chain.

Sources:

Bear Lodge Project (Rare Element Resources, OTC: REEMF)

Bear Lodge Project, located in Wyoming, is an advanced-stage rare earth development site owned by Rare Element Resources. The deposit is rich in high-strength permanent magnet rare earths, including neodymium, praseodymium, samarium, and terbium. The company has identified a near-surface, high-grade zone that could accelerate early cash flows once mining operations commence. Wyoming’s pro-business environment and existing infrastructure make Bear Lodge a promising domestic rare earth source.

Rare Element Resources is developing a rare earth processing and separation demonstration plant in Upton, Wyoming, designed to validate its proprietary extraction technology. The facility aims to produce up to 10 tons of separated Nd/Pr oxide, supporting strategic partnerships and potential commercial production. With funding from the Wyoming Energy Authority and collaboration with General Atomics, Bear Lodge is positioned to contribute to U.S. rare earth independence.

Sources:

Round Top Deposit (Texas Mineral Resources, OTC: TMRC)

Round Top Deposit, located in Texas, is one of the largest rare earth and critical mineral extraction sites in the U.S. Texas Mineral Resources, in partnership with USA Rare Earth, is developing this open-pit mine to produce heavy rare earth elements, lithium, uranium, and other strategic minerals. The deposit is estimated to contain over 1.1 million metric tons of rare earth oxides, making it a significant domestic resource.

The Round Top project benefits from its location on state-owned land, allowing for streamlined permitting and development. Texas Mineral Resources is working to establish a fully integrated rare earth supply chain, including refining and magnet production. With strong economic potential and government backing, Round Top is expected to play a crucial role in securing U.S. rare earth independence.

Sources:

Alaska Strategic Metals Complex (Ucore Rare Metals, OTC: UURAF)

Ucore Rare Metals is developing the Alaska Strategic Metals Complex (SMC), a planned rare earth processing facility near Ketchikan, Alaska. The facility will focus on refining heavy and light rare earth elements using Ucore’s proprietary RapidSX™ separation technology. The company has secured funding from the U.S. Department of Defense to advance its processing capabilities, aiming to establish a domestic rare earth supply chain independent of China.

Ucore’s long-term strategy includes expanding its refining operations beyond Alaska, with additional Strategic Metals Complexes planned in Louisiana and Canada. The company is positioning itself as a key player in North American rare earth processing, leveraging government support and partnerships to accelerate commercialization. With its advanced separation technology, Ucore aims to provide a reliable domestic source of rare earth elements for defense, clean energy, and high-tech industries.

Sources:

The Role of Government Policies in U.S. Rare Earth Development

Rare earth elements—despite their name—are everywhere! They power electric vehicles, wind turbines, and even military defense systems. But here’s the kicker: the U.S. imports most of its rare earths, with China controlling the lion’s share of global production and refining. To fix this, the U.S. is ramping up domestic mining and processing efforts, with federal incentives and funding aimed at reshoring rare earth supply chains. The Department of Energy has allocated millions to support rare earth refining projects, while defense initiatives seek to secure critical materials for national security.

Geopolitical tensions have only heightened the urgency. Trade disputes and export restrictions have disrupted rare earth supply chains, forcing the U.S. to accelerate partnerships with allied nations like Australia and Canada. The goal? Build a resilient, independent rare earth industry that can withstand global market fluctuations. But it’s a race against time—China’s dominance in refining and magnet production remains a formidable challenge.

Sources:

Market Trends and Outlook for U.S. Rare Earth Companies

The rare earth industry is booming! Forecasts show domestic production could grow at a compound annual rate of 9.2% through 2030, driven by surging demand for electric vehicles, defense applications, and consumer electronics. Neodymium and dysprosium—key components in high-performance magnets—are in particularly high demand as automakers shift toward EVs.

To meet this demand, U.S. companies are forming strategic partnerships with allied nations to secure rare earth supplies. Australia, Canada, and Japan are stepping up collaboration efforts, ensuring a diversified supply chain that reduces reliance on Chinese exports. As rare earths become even more critical to global industries, expect continued investment and innovation in domestic production.

Sources:

ESG and Sustainability Considerations

Rare earth mining isn’t exactly eco-friendly. Traditional extraction methods generate toxic waste, contaminate water sources, and disrupt ecosystems. But U.S. companies are working to change that! New sustainability initiatives focus on reducing environmental impact through cleaner refining technologies and responsible mining practices.

The future of rare earth extraction is looking greener, with bioinspired separation techniques and advanced recycling methods gaining traction. Researchers are developing eco-friendly processes that minimize waste and energy consumption, ensuring rare earth production aligns with global sustainability goals.

Sources:

Risks Facing U.S. Rare Earth Companies

China’s rare earth dominance is a major hurdle for U.S. companies. With control over more than 60% of global production and 85% of refining capacity, China sets the pace for pricing and supply. Competing with this monopoly requires massive investment in domestic refining and processing infrastructure.

Supply chain challenges also pose risks. Rare earth mining and refining require specialized facilities, and disruptions—whether from trade restrictions or logistical bottlenecks—can impact production. Market volatility adds another layer of uncertainty, with rare earth prices fluctuating based on geopolitical events and demand shifts.

Sources:

Investment Opportunities in U.S. Rare Earth Stocks

Investors looking to capitalize on rare earths have several options. Rare earth stocks offer direct exposure to mining and refining companies, while ETFs provide diversified portfolios that mitigate risk. Commodity futures allow investors to trade rare earth materials themselves, though they come with higher volatility.

The best strategy? A balanced approach. Investing in domestic rare earth companies with strong growth potential—like MP Materials and Ucore Rare Metals—while diversifying with ETFs can provide stability. As demand for rare earths continues to rise, these investments could offer long-term gains.

Sources:

Conclusion

Rare earth elements are the unsung heroes of modern technology—they’re in everything from your phone to fighter jets! The U.S. is ramping up efforts to mine and process them domestically, but there’s still a long way to go in competing with China’s refining dominance. With sustainable mining practices, advanced separation technologies, and strategic partnerships, the future of rare earths in America is looking bright. Science rules, and rare earths do too—so stay curious and keep exploring how these mighty metals shape the world!

🔥 Hot Topics in Material Stocks – Explore More! 🚀

Looking to level up your investment game? Dive into the hottest material stocks and rare earth sectors with these must-read articles! ⤵️

🏗️ Material Stocks & Sectors

🔥 High-Value Metal Stocks

🎯 Rare Earth & Advanced Materials

🚀 Keep exploring, keep investing! 💡 Let’s unlock the world of materials together!